|

| · Application |

|

|

| Environmental Protection |

Hydrotech privides membrane separation systems for the following applications:

- Recycle beneficial material in textile industries

- Emulsion Treatment in metal process

- Alkalis degrease agent recovery in automatic industries

- Coating emission treatment

- Phosphate liquid treatment

- Blood water treatment in slaughter mill

|

|

|

|

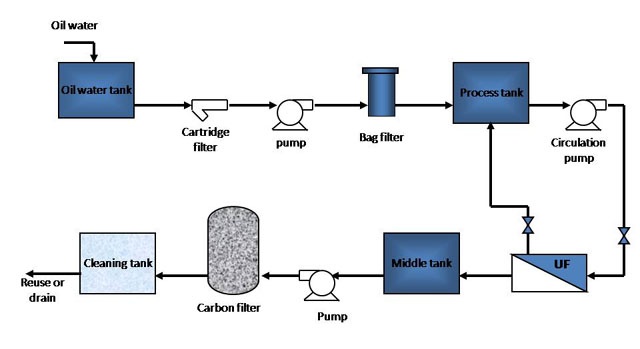

In today’s industry, people attach importance to the oil waste water. Because they call for the environmental protection and the green industry, so the result to treat the oil waste water will influence directly the maintenance and improvement for the water resource and environment.

Industrial oily wastewaters can be divided into three broad categories according to the distribution of the oil phase: Free-floating oil, Stable oil-water emulsions and sludge.

Stable oil-water emulsions are generated in many diverse industries. Metal working operations use water-soluble coolants, cutting and grinding oils, and lubricants fro machining. Metal cleaning tanks and alkaline degreasing baths generate an oily wastewater. Rolling and drawing operations use oil lubricants and coolants.

The stable oil-water emulsions are most difficult and at the same time most amenable to treatment by membrane technology. It can be very useful in extending the useful life of wash water and reducing the waste disposal problem, saving chemical coagulation/flotation.

Hydrotech provides the reasonable membrane systems to meet the needs according to the inquiry of our customers and the oil/water qualities.

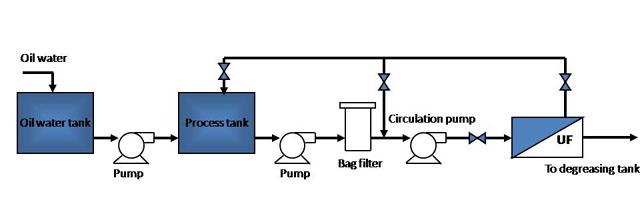

In Automobile industry, metal cleaning tanks and alkaline degreasing baths generate oil waste water which contains dirt, grease, alkali and solvent etc. The temperature of degreasing baths is around 55~70℃, so how to treat this waste water becomes a big concern. Now UF can be very useful in this application in extending the useful life of the rinsing water and reducing the waste disposal problem.

UF membrane can reject the oil in the waste water and recover the small molecular like alkali and solvent back to the degreasing baths for reuse. The concentrated oil can have 30 times reduction in volume.

UF oil/water separation system has many advantages: high efficiency, low energy cost, compact system, easy operation, good separation performance and recycle the alkali at the same time. With the low operation cost, high production rate and automatic control, UF system will meet the requirement of modern industry for high efficiency, environmental and low cost.

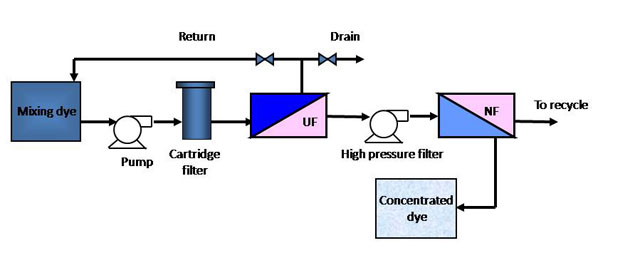

NF process can desalt and concentrate the dye. Reducing the salt from the dye can improve the printing intensity of the dye and produce a steady solvent condition for adding the assistant reagent. Liquid dyes request to remove nearly all of the salt from the dye in order to ensure the stability and solubility and improve the dyeing intensity.

Compared with the traditional pressure desalting filtration process, NF process can recycle the value material and save the raw material and assistant material, reduce the waste water drain, decrease dry cost and shorten the process.

The synthetic size is used to improve the strength and surface characteristics of warp yarns prior to weaving operations where they are subjected to considerable abrasion and tensile stress instead of the traditional warp sizing agents. Due to the high cost of synthetic sizes, the recovery and reuse is a much more attractive solution:

- Concentrate the size in the desizing both from 1-2% to 8-12% with Ultrafiltration (UF) system, recycled sizing can be reused in sizing process.

- Permeate from UF is the hot water (60 ~80°C), which can be reused in desizing process to save water and energy.

- The system can recover 80%~ 85% sizes to minimize the waste water treatment.

Hydrotech can provide the turn-key system including the small test, middle test, project design, equipment manufacture, system installation, commissioning for this application.

Following the scarce water resources and severe pollution, people pay much attention to the environmental protection and the energy recovery. Hydrotech has engaged in the research and development and the application of the industrial drainage for many years, at present, OCV MBR membranes have been used in the field.

After the treatment from the sewage plant in the E-coating workshop, the drainage feed into OCV MBR UF system and then RO system for the further treatment to recycle, which reduce the drainage volume, save the water and cut pollution.

|

|

|